What is Building Management System?

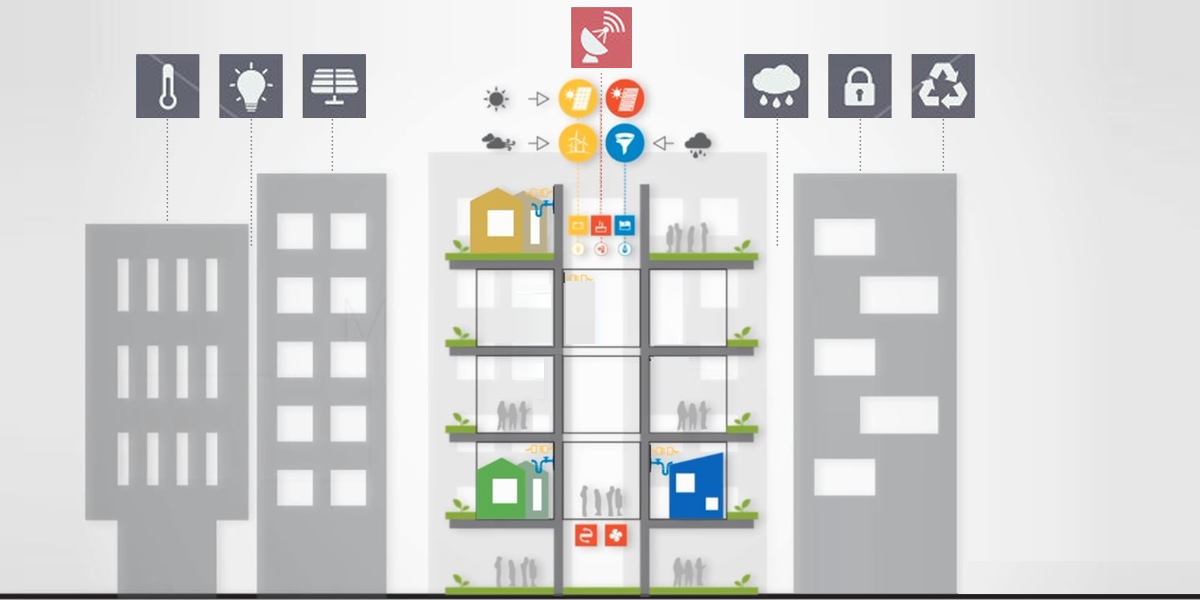

Building Management System (BMS) is a software solution which automates, monitors, manages, and controls and the entire mechanical equipment and electrical gadgets in a building and ensures the smooth functioning of the equipment. BMS is designed to follow some strategic rules and norms in order to achieve the requirements in any organization. BMS is also known as Building Automation System (BAS) as the entire building functions are automated to achieve the required results. The systems can be automated in such a way that it does monitoring in a systematic way and provide suggestions or predictions. BMS also comes with disaster-response mechanisms. BMS monitors and controls the entire building activities. Water supply system and security systems are part of the BMS.

What is Energy Management System?

Energy Management System (EMS) is a software solution used to monitor and control the electrical utilities in an organization thereby optimizing the energy consumption. EMS works based on the rules set for efficient utilization of energy. Energy is the most consumed utility in any organization. EMS considered as a subset of BMS. EMSs can check the performance and control the utilities connected to it. Energy utilization is optimized by controlling the electrical systems as per the predefined rules.

How BMS and EMS Work Together?

EMS manages the part of the BMS system where energy is concerned. It includes management of lighting system, Heating, Ventilation and Air Conditioning (HVAC) systems, and much more. BMS and EMS can also provide data visualization dashboards based on which you can monitor the real-time data and do the analytics. Complex reports can be generated using the BMS and EMS systems. It helps you to detect the problems before they actually occur.

In huge buildings, there are many numbers of mechanical and electrical units that are interconnected and works in coordination with the predefined set of rules. All the activities of equipment connected are captured in specific Controllers. These controllers are in turn connected to highly sophisticated BMS and EMS automation systems. The automation system reads the signals from the controller and analyses the input. Based on the specific rules defined in the system, it optimizes the energy consumption and usage by controlling the mechanical equipment.

Application of BMS and EMS

In huge multistory buildings, water supply systems, security controls, elevators, HVAC systems etc can be managed and controlled by BMS. Office Buildings, Malls, Manufacturing Plants, Movie Theatres, Hospitals, Universities are few of the organizations who can use BMS and EMS to effectively manage the resources and save their energy bills. Nearly 30% of the energy usage can be minimized using EMS.

For example, consider a big restaurant with many rooms. Practically, it is difficult to switch off and on lightings or control the lightings (dim or strong or of different colors) as per the time. You can control the switches using an EMS integrated to BMS. It will identify or sense the situation as per the predefined rules and controls the lights in the specific area. This a particular case of EMS where energy consummation is monitored and optimized.

Hotel booking also can be connected to the BMS. When a customer books a room, the controller gets the input regarding the same. The BMS can then manage the HAVC units in the room and lightings. If there is a chain of restaurants connected to the system, then the customer profile (requirements) can be stored and reused when they book rooms in any of these restaurants which are interconnected.

Benefits and Scope

- Huge buildings, malls, theaters, and chain of restaurants are a flourishing in metropolitan cities, where the energy consumption is a matter of fact as they require a huge amount of energy for their functioning. BMS/EMS can be used in a single building or group of buildings, institutions, universities etc.

- 24X7 monitoring is achieved via BMS/EMS. Automized monitoring and tracking systems detect the faults and flaws before they actually occur. Fault alerts minimize the damage caused due to faults and flaws.

- Resource requirement is minimized as the whole system is automized.